Liquid Screed in Wet Retail Areas: Risks and Requirements

Liquid Screed in Wet Retail Areas: Risks and Requirements

In commercial kitchens, bathrooms, and food prep areas, the presence of water is a constant. When specifying liquid screed for these zones, understanding the relationship between moisture and anhydrite binders is essential for a long-lasting floor finish.

1. The Sensitivity to Moisture

The primary risk identified by The Screed Scientist is the chemical nature of anhydrite (calcium sulphate) binders.

The Risk: If a calcium sulphate screed becomes saturated after installation, it can lose structural integrity. Unlike cement, which is hydraulic and sets under water, anhydrite binders can soften if exposed to prolonged moisture.

CSC Screeding Protocol: We ensure the screed is fully dried—to a moisture content of 0.5% water by weight (or 75% Relative Humidity)—before any floor finishes are applied.

2. Potential for Floor Finish Failure

In wet retail areas, the floor finish (such as non-slip vinyl or resin) acts as a waterproof barrier.

The Risk: If water bypasses the surface finish (through a leaking pipe or damaged seal) and gets trapped between the waterproof finish and the screed, it cannot evaporate. This trapped moisture can lead to "debonding," where the tiles or resin lift away from the screed surface.

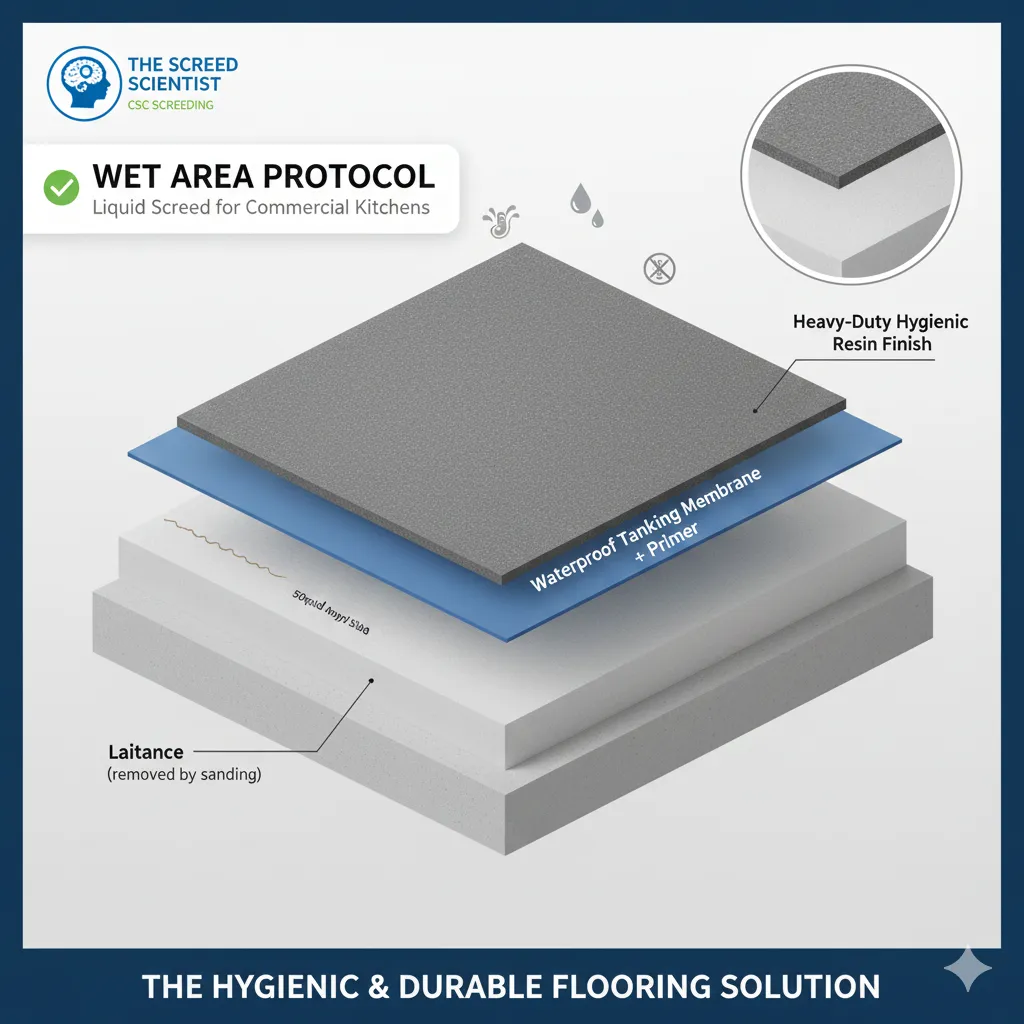

Prevention: CSC Screeding recommends the use of high-performance tanking membranes and waterproof primers in all high-moisture zones to protect the screed core.

3. Laitance and Adhesion

Wet areas often require high-strength epoxy or PU (polyurethane) resins for hygiene and slip resistance.

The Risk: All liquid screeds produce a thin layer of "laitance" as they dry. If this is not removed, the waterproof resin or adhesive will bond to the dust rather than the screed itself.

CSC Screeding Protocol: We insist on mechanical sanding to remove the laitance 7–10 days after pouring. This ensures a clean, open-textured surface that allows primers to penetrate deeply, creating a "mechanical lock."

4. Bacterial Growth and Hygiene

In commercial kitchens, hygiene is non-negotiable.

The Risk: Voids in a floor can harbor bacteria. Traditional sand and cement can be porous and difficult to compact perfectly.

The Advantage: Because liquid screed is self-compacting, it creates a high-density, void-free mass. When correctly sealed with a waterproof system, it provides a far more hygienic base than traditional methods because there are no internal air pockets for moisture to settle in.

Best Practice for Wet Retail Zones

Dryness First: Never apply a finish until the screed is confirmed dry via a Carbide Bomb or Hygrometer test.

Tanking is Mandatory: Use a dedicated waterproofing "tanking" system in kitchens and bathrooms.

Drains and Falls: Liquid screed is designed to be level. In areas requiring a "fall" to a drain (like a wet-room shower), traditional screed or a specialized cementitious liquid screed may be required to achieve the necessary slope.

Mechanical Preparation: Always sand the surface to ensure the waterproof membrane can bond effectively.

The Verdict

Liquid screed is perfectly suitable for wet retail areas, provided the installation follows the strict drying and tanking protocols set by CSC Screeding. By removing laitance and ensuring a "tanked" environment, the floor remains as durable and hygienic as the rest of the retail unit.

Would you like me to generate a simple technical diagram showing the layers required for a waterproofed retail kitchen floor?